A battery stacker, also known as an electric stacker or battery-powered stacker, is a type of material handling equipment that uses battery power to lift, stack, and transport loads. It is commonly used in warehouses, distribution centers, manufacturing facilities, and other industrial environments for efficient and sustainable material handling.

Here are some key features and characteristics of battery stackers:

Power Source: Battery stackers are powered by rechargeable batteries, usually lithium-ion or lead-acid batteries. The batteries provide the necessary energy to operate the lifting and propulsion systems of the stacker.

Lifting Mechanism: Battery stackers use hydraulic or electric lifting mechanisms to raise and lower loads. The lifting mechanism is powered by the battery and allows for smooth and controlled lifting.

Load Capacity: Battery stackers are available in various load capacities, ranging from a few hundred kilograms to several tons. The load capacity determines the maximum weight that the stacker can lift and transport safely.

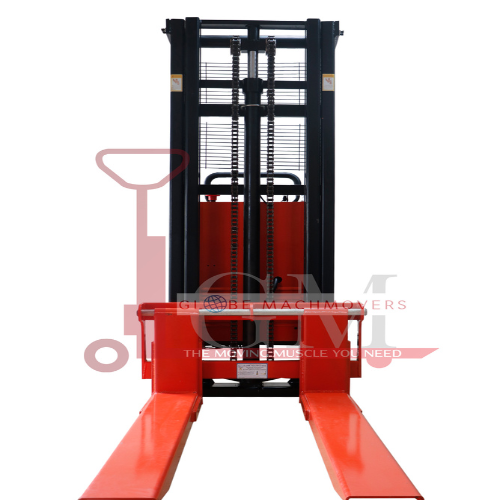

Forks: Battery stackers are equipped with forks that support and lift loads. The forks are typically adjustable in width to accommodate different pallet sizes. They can be raised and lowered using the lifting mechanism, allowing for precise load positioning.

Maneuverability: Battery stackers are designed to be highly maneuverable, offering ease of navigation in narrow aisles and confined spaces. They often have small turning radii and ergonomic controls for operator convenience and efficiency.

Battery Life and Charging: The battery life of a battery stacker can vary depending on factors such as the capacity of the battery, load weight, and operating conditions. Most battery stackers have indicators or meters to monitor the battery level. They are typically equipped with built-in chargers for easy and convenient charging when not in use.

Safety Features: Battery stackers are equipped with safety features to ensure operator and load safety. These may include safety switches, emergency stop buttons, load backrests, and stability-enhancing features to prevent accidents and protect operators.

Efficiency and Environmental Benefits: Battery stackers offer energy efficiency and environmental benefits compared to other types of stackers. They produce zero emissions during operation, making them suitable for indoor use and helping to create a cleaner and healthier working environment.

Control and Automation: Some battery stackers come with advanced control systems and automation features. These can include programmable settings, customizable operating modes, and integration with warehouse management systems for increased efficiency and productivity.

Battery stackers provide a sustainable and versatile solution for lifting and transporting loads. They offer quiet operation, reduced maintenance requirements, and improved energy efficiency compared to other types of stackers. When using a battery stacker, it’s important to follow safety guidelines, receive proper training, and adhere to the manufacturer’s instructions for battery maintenance and charging to ensure safe and efficient operation.

Battery stackers offer several benefits that make them advantageous in material handling operations. Here are some key benefits of using a battery stacker:

Environmental Friendliness: Battery stackers are environmentally friendly because they produce zero emissions during operation. Unlike combustion engine-powered stackers, they do not release pollutants or contribute to air pollution, making them suitable for indoor use and helping to create a cleaner and healthier work environment.

Energy Efficiency: Battery stackers are known for their energy efficiency. They convert electrical energy from the battery into mechanical power more efficiently compared to other types of stackers. This efficiency translates into longer operating times per charge and reduced energy consumption, resulting in cost savings over time.

Quiet Operation: Battery stackers operate quietly compared to combustion engine-powered stackers. This low-noise operation is beneficial in noise-sensitive environments such as warehouses, retail spaces, and manufacturing facilities, promoting a more comfortable and less disruptive work environment.

Improved Maneuverability: Battery stackers are designed to be highly maneuverable, allowing them to navigate narrow aisles and tight spaces with ease. They typically have a small turning radius and precise control systems, enabling operators to handle loads in confined areas efficiently.

Reduced Maintenance: Battery stackers generally require less maintenance compared to combustion engine-powered stackers. They have fewer moving parts, no engine oil, and do not require regular maintenance tasks such as fueling or changing filters. This results in lower maintenance costs and less downtime for maintenance activities.

Operator Comfort: Battery stackers are designed with operator comfort in mind. They often feature ergonomic controls, adjustable seats, and cushioned platforms, reducing operator fatigue and promoting better productivity. The quiet operation and absence of exhaust fumes further enhance the operator’s working environment.

Versatility: Battery stackers are versatile material handling equipment that can handle a wide range of loads. They are suitable for various applications and industries, including warehousing, distribution centers, manufacturing facilities, and retail stores. With different load capacities and lift heights available, battery stackers can accommodate different load sizes and stacking requirements.

Safety: Battery stackers are equipped with safety features to ensure operator and load safety. These may include emergency stop buttons, safety switches, load backrests, and stability-enhancing features. The absence of exhaust emissions also contributes to a safer and healthier work environment for operators and other personnel.

Overall, battery stackers offer a combination of environmental friendliness, energy efficiency, maneuverability, and operator comfort. They provide a sustainable and reliable solution for lifting, stacking, and transporting loads while promoting a safer and more productive work environment.